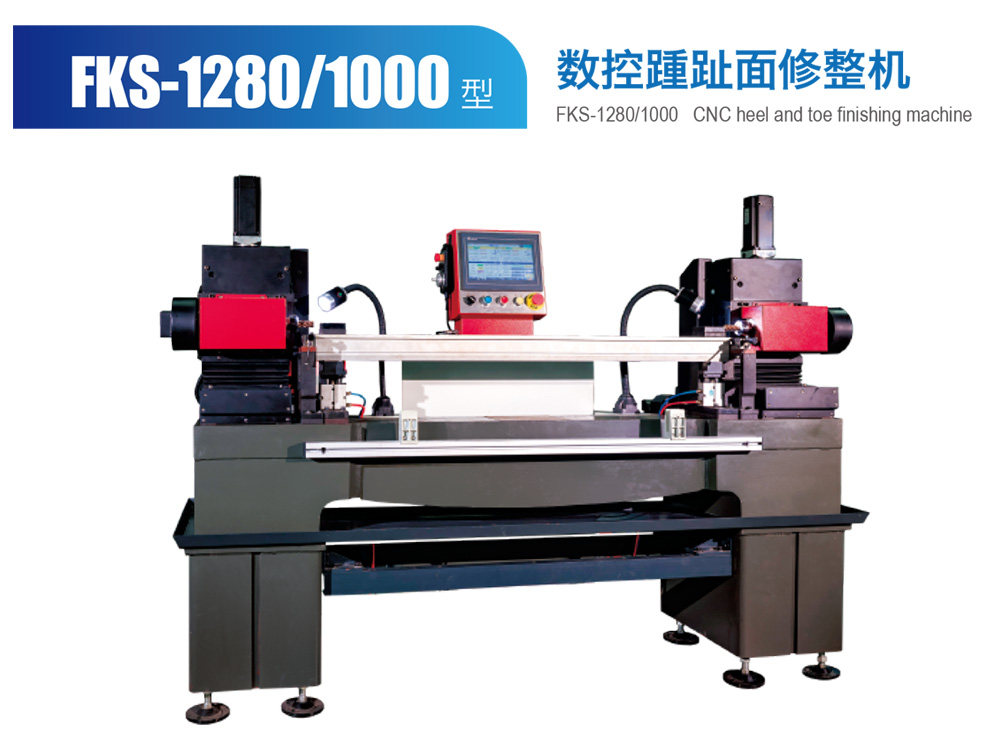

FKS-1280-1000-型数控踵趾面修整机

功能及特点 Function and characteristics

为确保加工精度,采用整体式结构,以提高机器的刚性强度,

采用高精度V型交叉导轨作为运动滑台,配合带刹车减速高精度伺服动力源,

使得X,Y方向运动曲线完美体现,二个方向的对龙骨夹持,保证铣削时工件振动小。

It plays an important role in improving the sharpness of

the worn cylinder clothing tooth tips, can extend the service

life of the clothing by more than 20%, is easy to install and use,

and has a short repair time.

整机采用10寸触摸屏界面和PLC的曲线逻辑算法,实现对踵趾差加工尺寸的严谨

控制,双头X,Y方向的零点调整极为方便直观,每个运动轴配置

有光栅尺反馈和机械零点,适配多条针对不同踵趾头形状的加工程序。

The machine adopts 10 inch touch screen interface and PLC curve logic algorithm

to achieve strict control of heel and toe difference processing size,

double head X,Y direction zero adjustment is very convenient and intuitive,

each movement axis is equipped with grating ruler feedback and mechanical zero,

suitable for a number of processing programs for different heel and toe shapes.

技术参数及规格 Technial Parameters

电 源 power supply 380V+PE

整机功率 Total power 3000W

适用加工盖板龙骨宽度 Machined cover keel width 33.3mm

适用加工盖板龙骨长度 Finish cover keel length

FKS-1000(type):1020mm

FKS-1280(type):1280mm

加工材质 Processed material 铸铁/合金钢 Cast iron/alloy steel

铣刀规格 Cutter specification 改20*40*100*6T

铣刀转速 Milling cutter speed 500-1200RPM

注:加工不同机幅要选用不同的机型,要求机幅通用可选择单头机型。

Processing different frames should be matched with different models,

requiring that the general frame can choose a single head model.